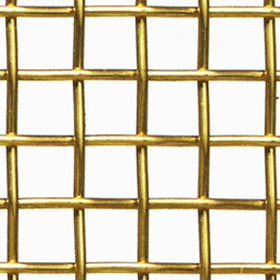

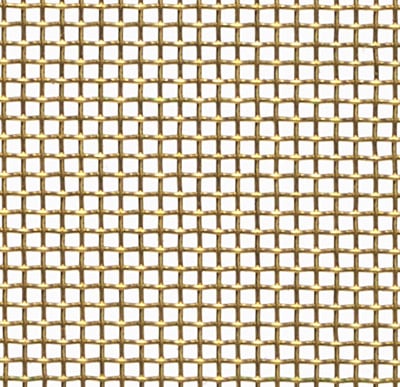

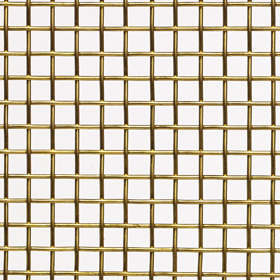

Brass is an alloy that is comprised of copper and zinc, and, like copper, brass is soft and malleable and is attacked by ammonia and similar salts. As a wire mesh, the most commonly available brass woven wire mesh is referred to as “270 yellow brass” and has a chemical composition of approximately 65% copper, 35% zinc. “260 high brass”, which consists of 70% copper and 30% zinc is also a popular in the mesh industry, particularly on custom manufactured items.

The presence of zinc in brass woven wire mesh is important because it provides added abrasion resistance and allows for higher tensile strengths; it also hardens the mesh, compared to its softer copper woven wire mesh counterpart. For these reasons, brass wire mesh is commonly used in filtration and separation applications, and it is used to fabricate discs, especially in instances when electrical conductivity is not critical.

In most cases, industrial grade brass woven wire mesh has a golden yellow color to it, and this unique color makes it appealing for use in architectural, decorative and even artistic applications. Most of the wire mesh specifications that Darby offers from stock can be cut to size with a pair of high-quality tin snips, or for many of the fine mesh options, a razor blade can be successfully used.

Like virtually all wire mesh and wire cloth, brass wire mesh is used in architectural, decorative and industrial applications. Here are a handful of common uses and industries that use brass woven wire mesh:

- Aerospace

- Marine use

- High end infill panels

- Room separation & dividers

- Unique artistic designs

- Decorative lamp shades

- Decorative signage

- RF amplification

- Metal artisans

- Ceiling panels

- Air & liquid filtration

- Fireplace screens

- Chemical processing & diffusion

- Cabinet screens

- Metal castings

- Power generation

- Oil strainers

- Plumbing Screens

- Soffit screen

- Gutter guards

- Air Vents

.png)

Connect with Darby