As early as 1870, Edward J. Darby & Son, Inc. was responsible for supplying various meshes to much of the eastern seaboard as the United States began to rebuild after the Civil War. Today, wire mesh remains a staple of the building and construction industries, and Darby continues to cement its reputation as a preferred supplier of the many different types of wire mesh that this industry commonly requests.

Because mesh is such a versatile industrial product, the building and construction industries tend to specify various meshes for use in a wide array of applications. These applications include, but are not limited to: architectural use, safety and enclosure use, wall and rock retention, and bridge and highway maintenance.

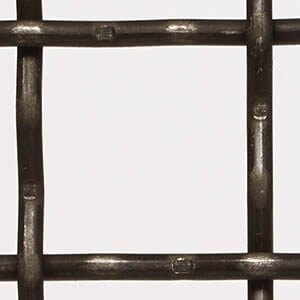

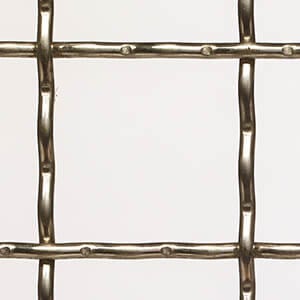

Welded specifications—in particular, Plain Steel, Galvanized and T-304 Stainless Steel – are fixtures in the building and construction industries. Generally speaking, welded wire mesh items are economical and offer larger opening sizes with thinner diameter wires that are commonly available for purchase in conveniently sized rolls or sheets.

Aside from construction projects, many of the wire meshes offered below are used in a wide range of building-related applications, including infill panels, enclosures and safety guards. Many of these specifications are customer-driven so it is important to thoroughly review the architect’s, the engineer’s or the project manager’s prints and notes. Darby is unable to make specific recommendations for specific applications.

Darby also specializes in supplying custom woven and welded wire mesh specifications.

The items listed below represent some of our customers’ most requested wire mesh specifications. Many of these items are available from stock or can be quickly custom manufactured. Should you not see your specification, please contact us to discuss your requirements.

Connect with Darby