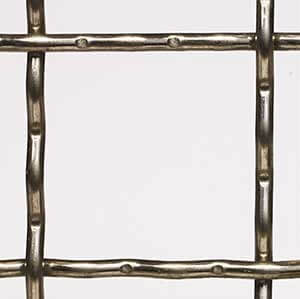

Monel 400® (International Nickel Co.) is a uniquely strong and durable material composed primarily of Copper and Nickel. As a copper-nickel alloy, Monel 400® exhibits high strength and excellent corrosion resistance in a wide range of media, including sea water and in acidic and alkaline environments. Due to these characteristics, Monel wire mesh specifications are often requested by naval shipyards and companies that specialize in marine technologies.

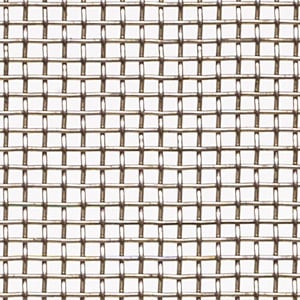

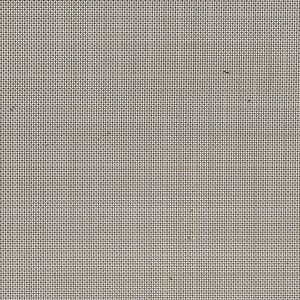

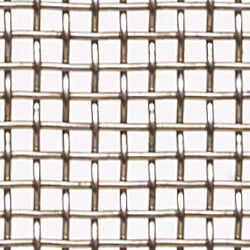

In the wire mesh industry, Monel 400 wire is drawn to specific diameter wires and woven to certain specifications. Monel woven wire mesh is commonly used in high performance applications, aerospace, chemical and hydrocarbon processing equipment, as well as in valves, pumps, shafts, fittings and heat exchangers. With a few exceptions, non-industrial users rarely opt for Monel wire cloth due to its high cost and similar appearance to stainless steel.

Records indicate that this alloy was readily available in the early 20th century, which is when Darby began to specialize in stocking the standard or market grade specifications of Monel 400. Today, Darby remains a leading source for these items. Darby also maintains the capabilities to weave numerous heavy duty Monel wire mesh specifications in diameter wires as heavy as 1/4” (.250”). With access to both domestic and international mills, Darby routinely offers custom manufactured Monel 400 pre-crimped woven wire mesh.

Monel 400 woven wire mesh is generally sold in quantities less than full rolls due to the high cost and long life cycle of this wire mesh alloy.

The chart below illustrates a typical chemical composition for Monel 400 wire cloth:

Typical Chemical Composition for Monel 400 Wire Mesh (in %) |

|||||||||||||

| Carbon [C] (Max) | Manganese [Mn] (Max) | Iron [Fe] Max | Copper [Cu] | Nickel [Ni] | S & Si | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.3 | 2.0 | 2.5 | 28.0-34.0 | 63.0 Min | Traces | ||||||||

Connect with Darby