T-316 stainless steel is recognized as the second most widely available of all stainless steels in the wire mesh industry. T-316 stainless steel wire mesh is typically considered an alternative grade to T-304 stainless steel wire mesh and preferred in certain circumstances. Particularly, in marine environments and in applications requiring heavy welding, T-316 stainless steel is commonly specified due to its many benefits.

T-316 stainless steel has excellent corrosion resistance, and in particular, performs well in its ability to resist pitting and crevice corrosion in warm chloride environments. The inclusion of molybdenum (Mo) is a major factor for the improved corrosion resistance compared to a T-304 stainless steel counterpart.

T-316 stainless steel is heat resistant and has good oxidation resist resistance to a temperature of approximately 1600oF in intermittent service and to a temperature of 1700oF in continuous service. T-316 SS is also excellent for fabrication purposes – it can be formed and cut to size with appropriate tools and machinery. It also has outstanding weldability, and it is virtually non-magnetic in the annealed condition.

While T-304 stainless steel wire mesh is generally more popular and more readily available in a wide array of specifications, T-316 stainless steel wire mesh is often used and found in applications and industries highlighted below:

- Marine technologies

- Pharmaceuticals

- Chemical processing

- Food preparation & processing

- Rubber, plastic machinery

- Boat & yacht fittings

- Scientific & laboratory use

- Automotive

- Refinery & oil field

- Aerospace

- Particle separation

- General industrial use

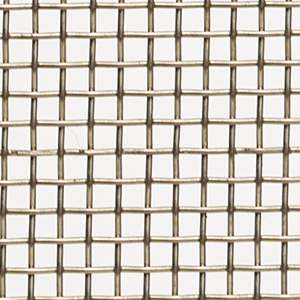

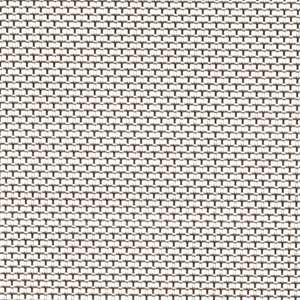

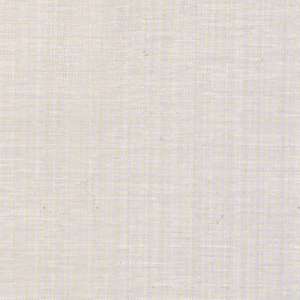

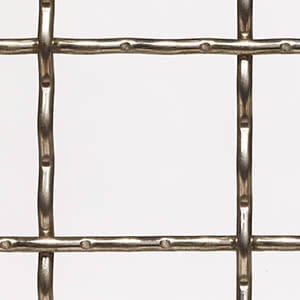

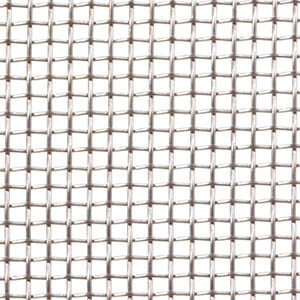

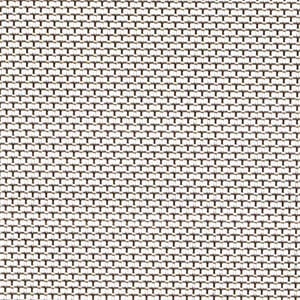

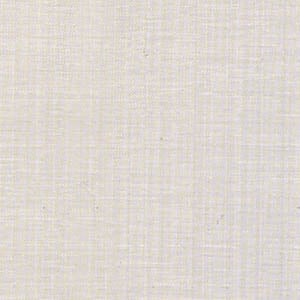

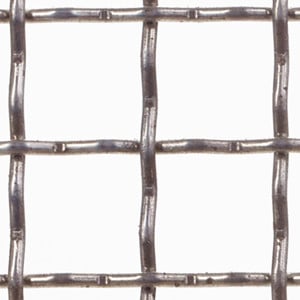

T-316 stainless steel is available in both woven and welded constructions – both from stock and through custom manufacturing. Below is the standard chemical composition for T-316 SS commonly used in the wire mesh and wire cloth industry:

T-316 Stainless Steel – Standard Chemical Composition (in %) |

|||||||||

| Alloy | Carbon [C] | Manganese [Mn] | Phosphorus [P] | Sulfur [S] | Silicon [Si] | Chromium [Cr] | Nickel [Ni] | Iron [Fe] | Others, if Applicable |

|---|---|---|---|---|---|---|---|---|---|

| T-316 | 0.08 Max | 2.00 Max | 0.045 Max | 0.03 Max | 1.00 Max | 16.00–18.00 | 10.00–14.00 | Balance | Mo = 2.00-3.00, N = 0.10 Max |

| Mo = Molybdenum; N = Nitrogen | |||||||||

.jpg)

Connect with Darby